|

Tianjin Jiu Peng Machine Tool Cutter Trade Co., Ltd

|

Bfl CNC Lathe Machine Tools Carbide Acrylic Engraving Milling Cutters Single Flute End Mill

| Price: | 10.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Tianjin, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1> HRA:91.8-92.4

2> TRS:>3800N/mm2

3> CO:13%, WC:87%

4> Grain size: 0.5-0.6um

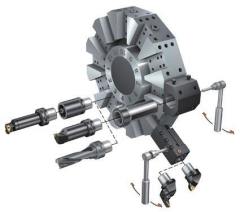

BFL-Double Flute Indexable CNC Mill/China Made Tool Set

1> HRA:91.8-92.4

2> TRS:>3800N/mm2

3> CO:13%, WC:87%

4> Grain size: 0.5-0.6um

Non-standard size of tools are available according to drawings.

1,Good quality

All tools are made by Michael Deckel from Germany. ANCA from Australia,guarantee high quality and good performance.

Every end mill is inspected by ZOLLER measuring and inspecting machine.

2,Super and stable raw material

1> YG10X--HRC45

2> YL10.2--HRC55, CB Carbide--HRC55

3> K44 from Germany--HRC60, Taegutec Carbide UF09 from Korea--HRC60

4> H10F Carbide--HRC65

3,Super coaing

Jiupeng coating make the cutter life longer, improve the smoothness, reduce the coefficient of friction.

Layer with super coating can be in high speed processing.

4,High reputation

We have many distributors or wholesalers in many countries, such as Turkey, Indonesia, Brazil, Peru, Poland, Italy,etc.

Welcome to be our agents, OEM is also accepted.

5,Reasonable price

Our main customers are wholesalers,so we will give you distount price if you make a bulk order.

6,Short delivery time

We keep a stock of fast moving items so that urgent orders can be met from stock quickly.

Maritime,courier and air etc.

Here are the detailed specifications as follows. Welcome to contact me if you have interests in our products.

| Order No. | Flute dia (d) | Cutting length ( l ) | Shank dia (D) | Overall length(L) |

| 1.0×3×4D×50L | 1.0 | 3 | 4 | 50 |

| 1.5×4×4D×50L | 1.5 | 4 | 4 | 50 |

| 2.0×6×4D×50L | 2.0 | 6 | 4 | 50 |

| 2.5×7×4D×50L | 2.5 | 7 | 4 | 50 |

| 3.0×8×4D×50L | 3.0 | 8 | 4 | 50 |

| 3.5×10×4D×50L | 3.5 | 10 | 4 | 50 |

| 4.0×11×4D×50L | 4 | 11 | 4 | 50 |

| 4.5×13×6D×50L | 4.5 | 13 | 6 | 50 |

| 5.0×13×6D×50L | 5.0 | 13 | 6 | 50 |

| 5.5×13×6D×50L | 5.5 | 13 | 6 | 50 |

| 6.0×15×6D×50L | 6.0 | 15 | 6 | 50 |

| 6.5×15×8D×60L | 6.5 | 15 | 8 | 60 |

| 7.0×17×8D×60L | 7.0 | 17 | 8 | 60 |

| 7.5×17×8D×60L | 7.5 | 17 | 8 | 60 |

| 8.0×20×8D×60L | 8.0 | 20 | 8 | 60 |

| 8.5×23×10D×75L | 8.5 | 23 | 10 | 75 |

| 9.0×23×10D×75L | 9.0 | 23 | 10 | 75 |

| 9.5×25×10D×75L | 9.5 | 25 | 10 | 75 |

| 10.0×25×12D×75L | 10.0 | 25 | 12 | 75 |

| 10.5×28×12D×75L | 10.5 | 28 | 12 | 75 |

| 11.0×28×12D×75L | 11.0 | 28 | 12 | 75 |

| 11.5×28×12D×75L | 11.5 | 28 | 12 | 75 |

| 12.0×30×12D×75L | 12.0 | 30 | 12 | 75 |

| 13.0×33×16D×100L | 13.0 | 33 | 16 | 100 |

| 14.0×35×16D×100L | 14.0 | 35 | 16 | 100 |

| 15.0×38×16D×100L | 15.0 | 38 | 16 | 100 |

| 16.0×40×16D×100L | 16.0 | 40 | 16 | 100 |

| 17.0×40×20D×100L | 17.0 | 40 | 20 | 100 |

| 18.0×40×20D×100L | 18.0 | 40 | 20 | 100 |

| 19.0×40×20D×100L | 19.0 | 40 | 20 | 100 |

| 20.0×40×20D×100L | 20.0 | 40 | 20 | 100 |

| 25.0×40×25D×100L | 25.0 | 40 | 25 | 100 |

SQUARE/FLAT End Mills offered are solid carbide mill finish that is suitable for metal options like aluminum, non-ferrous, non-metallic metal. Featuring precision engineered flute design that provides for superior chip removal at high feed rates, these end mills also allows for achieving lower cutting forces as well as enhanced balance and finish support. These also help in providing enhanced functional control as well as in bringing reduction in chatter.

Features:

Solid carbide mill finish that is suitable for metal options like aluminum, non-ferrous, non-metallic metal

Precision engineered flute design that provides for superior chip removal at high feed rates

Allows for achieving lower cutting forces

Features enhanced balance and finish support

Helps in enhancing control as well as in bringing reduction in chatter

Comes with exceptional performance support